India is rapidly developing as a global manufacturing hub, supercharged by Government initiatives like Make in India and global investor participation. Locational advantages, economies of scale and scope, low labour costs, Ease of Doing Business, and a significantly large domestic market are attracting foreign direct investments. The trend of global supply chain diversification as well as strategic realignment policies such as China Plus One and Look East are further fuelling manufacturing sector growth in India.

In this article, we have covered some of the emerging trends in the manufacturing sector, both globally and in the Indian context, the role of surveillance in smart manufacturing practices, and the challenges of implementing AI surveillance in manufacturing facilities.

What are the Emerging Trends in Manufacturing in 2025?

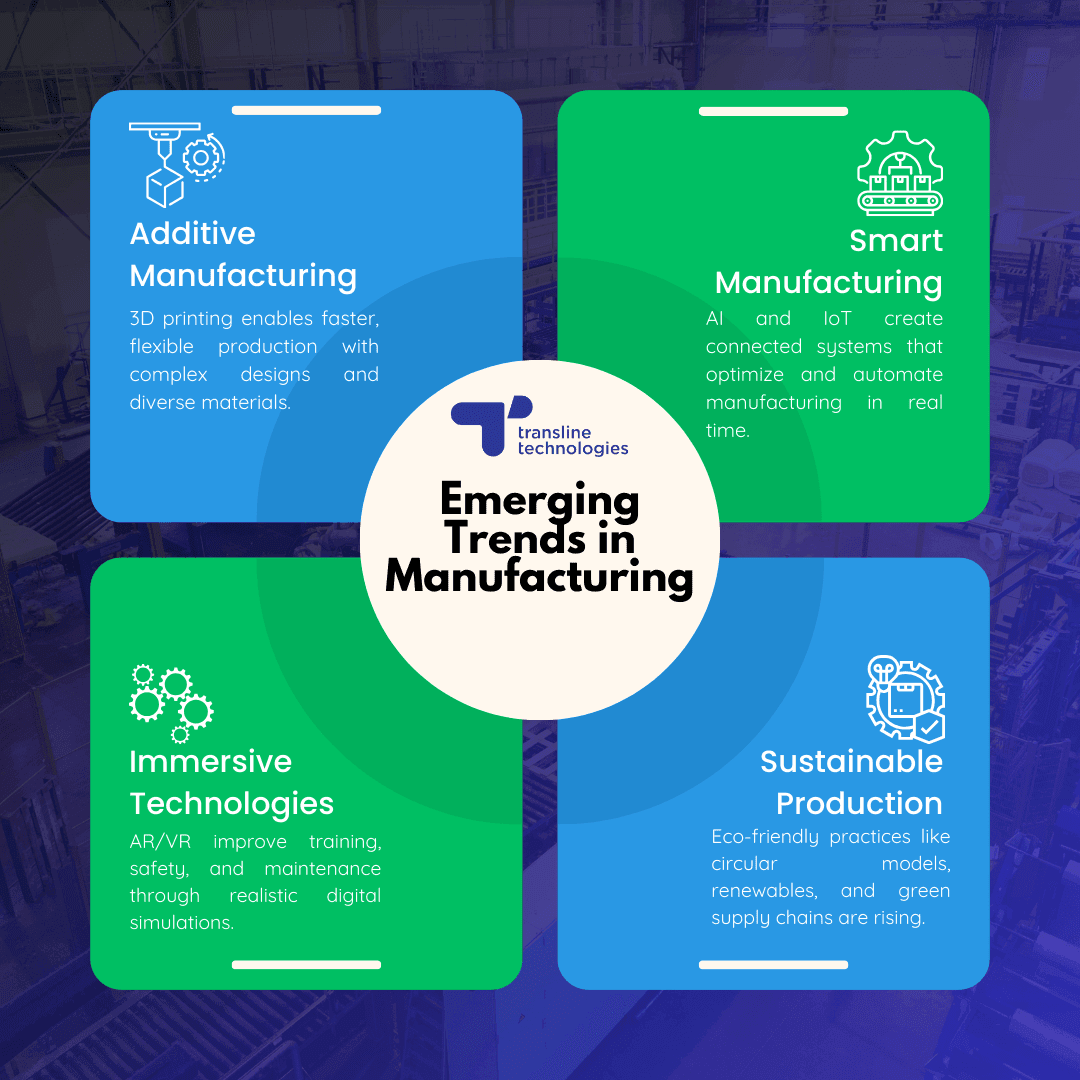

Over the past two decades, the manufacturing sector has seen a significant evolution, powered by robotics, advanced production processes, additive manufacturing, and industrial automation, powered by IoT and AI. While India was not one of the early adopters of these trends, apart from additive manufacturing, the Indian manufacturing space has now been witnessing a rapid implementation of these new technologies. We shall now discuss in brief some of the key emerging technologies and trends in manufacturing.

Additive Manufacturing

Additive Manufacturing collectively refers to all advanced production processes that deploy layer-by-layer generation of 3D objects from digital models, rather than material removal (which is the core tenet of traditional subtractive manufacturing). Also popularly known as 3D printing for small-scale manufacturing operations, Additive Manufacturing is one of the most promising technologies of the future, due to its ability to generate complex geometries (which were earlier not possible with material removal techniques), compatibility with diverse materials (metal powders, plastics, ceramics, composites, glass etc.). Stereolithography, Fused Deposit Modeling, Selective Laser Sintering, Direct Material Laser Sintering, Electron Beam Melting, Laminated Object Manufacturing, Ultrasonic Additive Manufacturing, Directed Energy Deposition-Arc and Vat Polymerisation are some of the most popular technologies in modern manufacturing setups.

Smart Manufacturing

Smart Manufacturing, also known as Intelligent Manufacturing, is a growing global trend, in which traditional manufacturing systems are connected by advanced IoT sensors, and deploy AI and real-time data analytics to create a responsive ecosystem. The incorporation of routine-task automation into the manufacturing system helps to reduce manual errors and improve cost-efficiency. As production managers get real-time visibility into every step of the manufacturing process with intelligent insights and do not have to separately check the measurements from every sensor, it becomes easier for them to troubleshoot anomalies. Moreover, the machine learning algorithms can analyse historical data from IoT sensors and combine it with real-time status reports to forecast predictive manufacturing schedules.

Immersive Technologies

Virtual Reality, Augmented Reality and Mixed Reality are becoming popular in the manufacturing space for training on critical equipment and safety induction. Age-old training processes, involving several pages of documentation and risky hands-on training on hazardous equipment, can be replaced with Mixed Reality for a safe and swift training experience. Moreover, MR-based training can be administered remotely, with reduced costs and waste, thereby improving the manufacturing companies’ bottomline. Even for production managers, it becomes easier to generate Digital Twins to visualise the floor layout, monitor the lifecycle of machinery and equipment, and conduct targeted predictive maintenance.

Sustainable Production

Sustainable Production is an emerging global trend, driven not just by compliance mandates, but evolving ESG adoption by global manufacturing enterprises. Sustainable Production encompasses the following aspects:

- Circular Manufacturing – It helps to reduce waste generation at the source and ensure more optimal resource utilisation, through use and life extension models, value recovery and circular support models, and the principle of the 4Rs.

- Renewable Energy Integration – Manufacturing companies are trying to reduce their carbon footprint by increasing their dependance on renewable energy sources instead of conventional thermal power. Setting up captive solar power plants is a growing trend in Indian manufacturing plants.

- Green Supply Chains – It is a modern approach to supply chain management, focussed on responsible sourcing, sustainable inventory management and minimisation of carbon footprint in logistics and transportation.

- Reshoring and Near-shoring - This refers to the change in global trade policies to shorten overseas transportation paths, and moving the manufacturing operations of a company closer to its core market (either the same country as in case of reshoring, or in a neighbouring country as in case of nearshoring).

What Role is Surveillance Playing in Smart Manufacturing?

Out of all the emerging trends, Smart Manufacturing is gaining the most popularity in the Indian manufacturing landscape due to the unique dynamics at play. And at the core of Smart Manufacturing lies the need for accurate surveillance and data capture. In smart manufacturing, factory CCTV and manufacturing surveillance systems capture high-resolution visual data from production environments, feeding it into AI and machine vision algorithms for real-time image analysis. These systems interface with IoT devices and edge computing platforms to detect anomalies in mechanical operations, calibrate robotic systems, and validate visual parameters. Seamless integration with manufacturing execution systems (MES) enables automated process validation and advanced visual analytics across the production network.

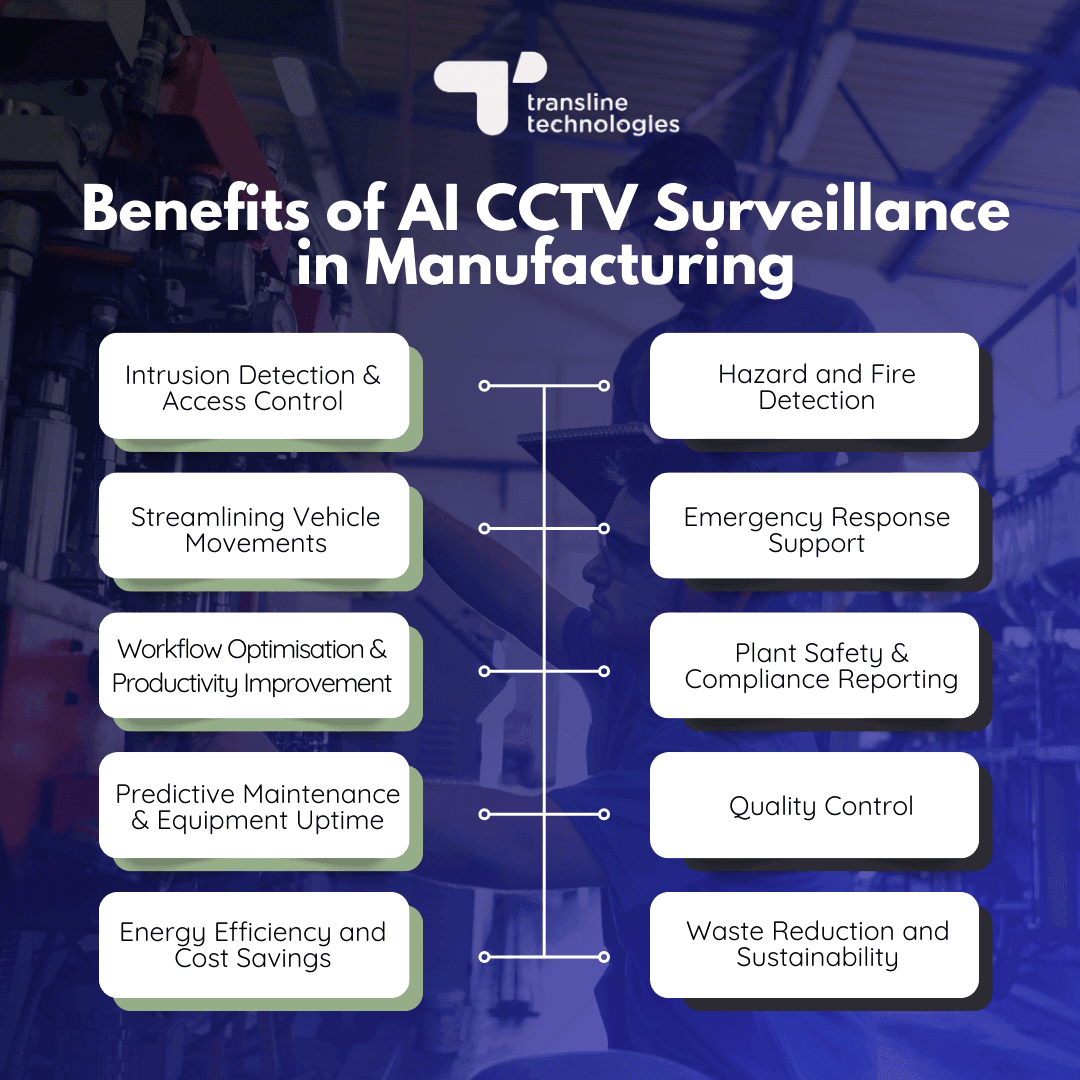

Top Benefits of AI CCTV Surveillance in Manufacturing

While AI manufacturing surveillance cameras have a vast range of applications and benefits, we will discuss in brief about the most common benefits, more specifically from an Indian context.

Real-Time Intrusion Detection and Access Control

AI surveillance cameras detect malicious activities in real time, distinguish between authorised employees and potential trespassers in manufacturing facilities. Facial recognition cameras at restricted zones within the factory premises can trigger real-time alerts whenever any unauthorised person (can be even an employee, who is not permitted to visit a specific zone) attempts to breach into that zone.

AI CCTV camera systems can also analyse behavioral patterns in real-time and detect whenever someone tries to steal machinery, throw something or cause damage to property, thereby enhancing security in manufacturing facilities.

Hazard and Fire Detection

AI factory CCTV camera systems can detect early indications of fire, such as weld spatter, fumes, latent flames etc. Moreover these systems can trigger live alerts whenever a potential health hazard is detected, and bolster employee safety within the factory premises. For instance, leakages in gas pipelines can be detected if the gas is of an identifiable colour. Oil spills from offshore oil rigs can also be readily detected using AI CCTV cameras, thereby minimising the environmental impact.

Streamlining Vehicle Movements

Manufacturing CCTV cameras can identify the type of vehicle based on their dimensions and frontal characteristics, by using AI algorithms, and monitor the vehicle movements. This information can be used in real-time to route incoming vehicles to the respective sections of the factory. Automatic Number Plate Recognition is another AI-powered technology that can be integrated with manufacturing surveillance systems to identify and keep a track of every vehicle that enters or exits the factory premises. Factory CCTV cameras can also track whether the vehicle tracks are clear of human movements and thereby operate in-plant traffic signals, thereby maintaining plant safety.

Emergency Response Support

Factory CCTV cameras help fire and emergency response personnel to find out if any employee is trapped at any part of the plant, and readily rescue them. This helps to enhance employee security within the factory, while also maintaining video footage records of emergency evacuation exercises for future legal purposes.

Workflow Optimisation and Productivity Improvement

Factory CCTV cameras help uncover new avenues of productivity improvement by identifying mismanagement of WIP items on the shop floor, reducing the muda of over-movement, detecting production bottlenecks. Moreover, manufacturing surveillance cameras facilitate quick diagnosis and troubleshooting at multiple plants from a central location (say, the headquarters of a company), thereby saving travel time and costs for the senior engineering team members.

Plant Safety and Compliance Reporting

Employees and visitors in manufacturing plants often do not adhere to the safety rules, and it becomes very difficult for safety inspectors to manually monitor every zone simultaneously, especially when the plant premises are spread over several acres of land. Here is where factory CCTV cameras, powered by AI and advanced video analytics, come to the rescue. AI manufacturing surveillance cameras can detect helmet and PPE kit non-compliance in real time and raise alerts to the safety officer, with details of the location within the plant where the breach occurred. Similarly, AI-powered factory CCTV cameras can track any incident of mobile phone usage or other safety violations by any employee in a prohibited zone of the plant.

Predictive Maintenance & Equipment Uptime

Deep learning algorithms can analyse video feeds from manufacturing surveillance cameras, and combine these with input signals from IoT sensors to detect anomalies in the operational characteristics of machinery, such as cracks in rotating shafts, excessive vibrations, leaks in bag-filters etc. By combining historical breakdown data and ideal lifecycle expectations, the AI algorithms can generate comprehensive reports of predictive maintenance requirements for critical equipment. This helps minimise unplanned equipment downtime, while also improving the lifespan of machines.

Quality Control

Factory CCTV cameras are installed at appropriate locations to aid quality inspectors in their daily task. For instance, during Shaping and Planing operations, AI-powered CCTV cameras ensure that the tool and bed are correctly aligned, and raise alerts whenever there are excessive vibrations or anomalies in the reciprocatory motion. At the inspection bed, manufacturing surveillance cameras can detect defects (such as cracks, misalignments, missing components etc) in the manufactured products before packaging. High precision manufacturing CCTV systems are nowadays deployed in additive manufacturing setups to further improve the production processes’ accuracy, especially in medical equipment, electronics and auto-components manufacturing.

Energy Efficiency and Cost Savings

Manufacturing surveillance cameras, when integrated with AI-powered video analytics solutions, can smartly trigger alerts when lights are unnecessarily on in any zone of the plant where no human presence is detected. In machining workshops, manufacturing CCTV cameras can detect when lathes, drilling machines or such other machine tools are operating in an unloaded condition (no job is held in the chuck) and raise alerts, thereby helping save electricity costs. AI-powered factory CCTV cameras can also be programmed to implement Daylight Saving Time in manufacturing facilities.

Waste Reduction and Sustainability

Manufacturing CCTV cameras help realise the vision of a circular economy by precise detection of waste-generation right at the source, monitoring whether hazardous items are disposed in the prescribed manner, and ensuring sustainable practices on the shop floor. AI-powered manufacturing surveillance cameras help reduce carbon dioxide and other greenhouse emissions by monitoring the efficacy of bag filters and electrostatic precipitators in real time.

Challenges with AI Surveillance in Manufacturing

In spite of all the benefits associated with manufacturing CCTV systems, there are some challenges and roadblocks in implementing factory CCTV surveillance cameras in the Indian industry. We discuss some of these setbacks in brief here.

Cyber-Attacks and Smart Manufacturing Vulnerabilities

Hackers can target the software solutions that drive smart manufacturing facilities to introduce malicious code into the systems, which may either disrupt the processes altogether or leak sensitive production-related data to competitors. According to a news report, over half of India’s Smart Manufacturing companies faced greater than six cyber-intrusions in FY23-24. Globally, the beverages industry faces the greatest cybersecurity risks with smart manufacturing systems. Hence, implementing the highest standards of cybersecurity is crucial in smart manufacturing setups.

Privacy Concerns and Legal Implications

As per the laws, the employer must obtain explicit consent from the employees, workers and other persons on the manufacturing shop-floor before commencing CCTV surveillance. Privacy concerns have been raised by workers’ unions in several plants after CCTV cameras were installed within the factory premises, with some union leaders claiming that it adversely impacts the mental health of workers.

Integration, Compatibility and Scalability Issues

Some of the analog manufacturing CCTV cameras installed in old factory premises are not integrable with modern AI-powered video analytics solutions, and this poses a serious hindrance in digital adoption for manufacturing companies. Moreover, high CCTV video storage costs, internet bandwidth limitations, power outages and maintenance requirements make it difficult to scale such manufacturing surveillance systems across all the production units of a company.

The Future of Manufacturing Surveillance

At Transline Technologies, we are spearheading the penetration of Artificial Intelligence, IoT and Advanced Video Analytics in the Manufacturing space. Our AI-powered CCTV Surveillance systems enhance worker safety and overall plant safety, while optimising productivity and streamlining manufacturing operations. StorePulse AI, powered by Transline Technologies, solves some real problems being faced by manufacturing enterprises, such as entry and exit counts of vehicles in the factory, helmet and PPE compliance, loading and unloading operations etc. We are committed to building sustainable technology solutions to empower Smart Manufacturing ecosystems for the Indian industry.

Connect with Us today to explore how to boost security in manufacturing units and enhance worker safety with advanced manufacturing surveillance systems.